Big businesses create a lot of waste, and most of it doesn’t need to end up in a bin. But moving towards zero waste takes more than good intentions. It means rethinking how things are bought, used and disposed of across your organisation.

This guide breaks it down into manageable steps, using well-established principles like the UK waste hierarchy and circular economy thinking to help you make real progress with enterprise recycling.

If you’re responsible for reducing business waste across a large organisation, this is a good place to start.

What “zero waste” really means for big businesses

“Zero waste” is a term often used loosely, but if you’re building a strategy around it, the detail matters.

The most widely recognised definition comes from the Zero Waste International Alliance (ZWIA). It defines zero waste as:

“The conservation of all resources by means of responsible production, consumption, reuse, and recovery of products, packaging, and materials without burning and with no discharges to land, water, or air that threaten the environment or human health.”

In simple terms: zero waste isn’t only about avoiding landfill. It means preventing waste in the first place and making sure that anything left over can be reused, recycled, or recovered in a way that doesn’t cause harm.

That’s why “zero waste” and “zero waste to landfill” aren’t the same. Zero to landfill is a positive step, and often part of a wider zero-waste journey, but it doesn’t necessarily mean that nothing is burned or lost from the system. A full zero-waste approach goes further by prioritising prevention, reuse and true resource recovery. Being clear on the difference helps you set the right goals, track the right metrics, and build trust with stakeholders.

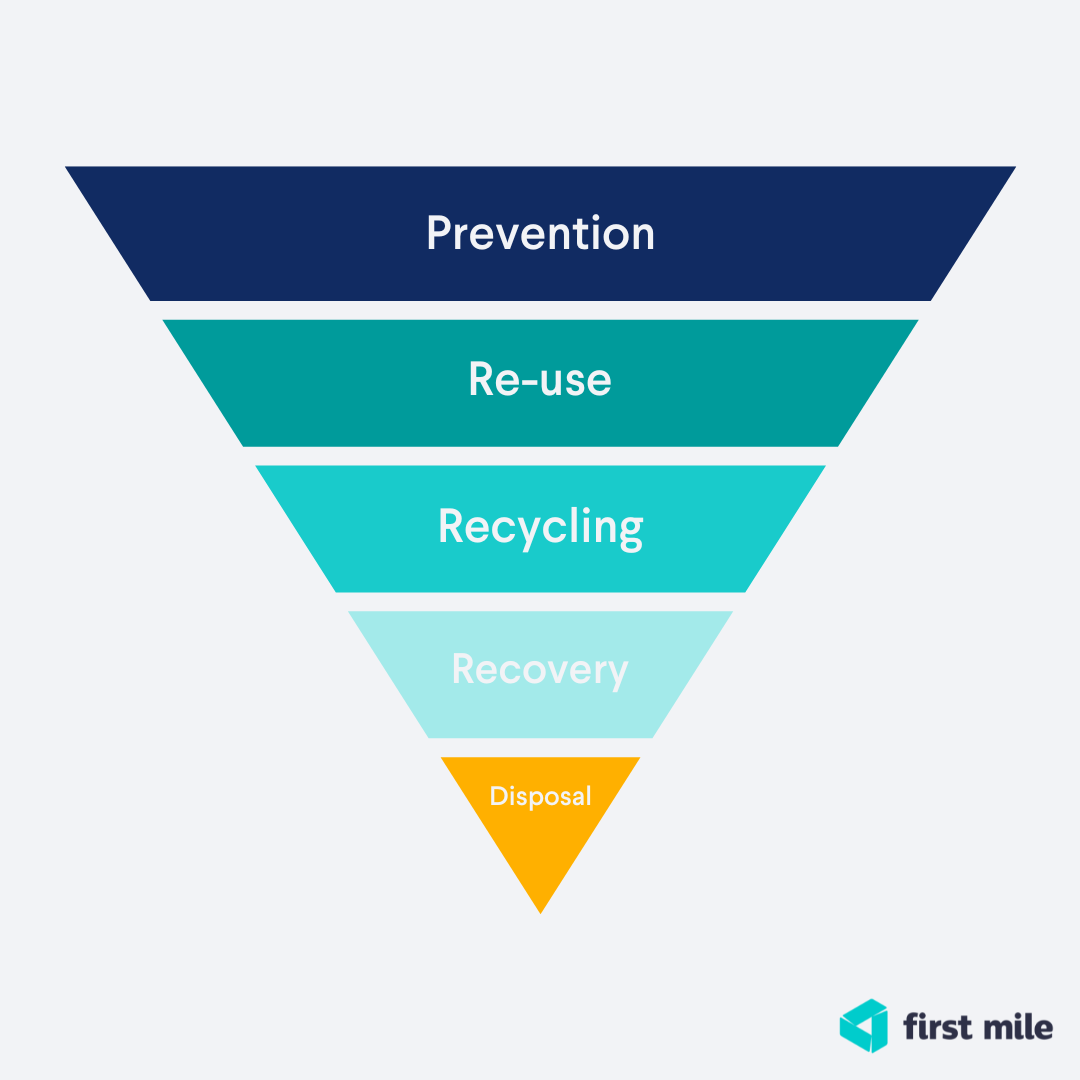

In the UK, the waste hierarchy underpins how businesses are expected to manage waste, ranking options from most to least sustainable. Familiarising yourself with this structure as a business is key to building a credible zero-waste strategy and staying compliant.

Start with the waste hierarchy

The UK’s waste hierarchy is a framework that helps businesses manage waste responsibly. It ranks actions from most to least sustainable, and it’s the best starting point for building an effective zero-waste strategy.

Here’s how it breaks down, with examples tailored to enterprise-scale operations:

Prevention

Stop waste before it starts. This could mean switching to refillable cleaning supplies, removing unnecessary packaging, or updating processes to avoid over-ordering stock.

Reuse

Find ways to use items again before discarding them. Refurbished IT equipment, reusable delivery crates, and a central office supplies cupboard for redistributing spare materials are all good places to start.

Recycling

Make sure anything that can be recycled, is. Set up proper segregation for materials like paper, cardboard, glass, food, and WEEE (electricals) across your sites.

Recovery

If recycling isn’t an option, energy recovery is the next step. This turns waste into fuel so it stays out of landfill and still serves a purpose.

Disposal

This is the last resort. Anything that ends up in landfill represents a lost resource and a cost to your business and the planet.

Being familiar with the business waste hierarchy is essential for corporate waste reduction. Prevention and reuse often offer the biggest environmental and financial wins, especially at scale. Starting here can help you cut waste and costs at the same time.

Build in circular economy principles

A zero-waste strategy works best when it’s part of a bigger shift, from a take-make-throw model to a circular one.

The circular economy is all about keeping resources in use for as long as possible. That means designing products and systems to reduce waste, extend lifecycles, and regenerate natural resources, rather than depleting them.

One useful approach is cradle-to-cradle thinking, which looks at how materials flow through your organisation and plans for reuse, repair or recycling from the outset.

Here’s what that can look like in practice:

- Product-as-a-service: Lease equipment like printers or furniture with built-in maintenance and return schemes.

- Repair and maintenance programmes: Extend the life of uniforms, electronics or machinery through scheduled upkeep and repairs.

- Remanufacturing: Work with suppliers to return used components for rebuild and resale.

- Internal reuse and resale: Set up systems to reallocate surplus stock or sell on unused assets before disposal.

These principles can reduce procurement costs, unlock new value streams and make reporting on Scope 3 waste more meaningful, all while supporting your business’s sustainability targets.

Make procurement and design work for zero-waste

Waste is often designed in, which means it can be designed out.

From packaging and materials to equipment and fit-outs, procurement plays a big role in how much waste your business generates. Bringing zero-waste thinking into your purchasing decisions can have a big impact, especially across multiple sites.

Here are some ways to get started:

- Specify recycled content in everything from packaging to paper to construction materials.

- Choose modular or repairable products (like furniture or tech) that can be fixed or upgraded rather than replaced.

- Design for disassembly, so materials can be separated and recycled at end of life.

- Work with suppliers on take-back schemes that keep materials in use longer.

- Include zero-waste goals in contracts, making it clear what’s expected and how it’ll be measured.

It’s also worth aligning teams early on. Procurement, facilities and sustainability teams should work together from the start of a project, whether you’re opening a new site, rolling out new kit, or changing suppliers. That way, commercial recycling best practice and waste prevention become part of the plan, not an afterthought.

Collect and report the right data

To reduce waste across a large organisation, you need to know what you’re dealing with and where it ends up.

This is especially important if you're reporting on your environmental impact. Many businesses now track what's known as Scope 3 emissions (indirect emissions that come from your supply chain and other business activities). One part of this, called Category 5, covers the waste your operations produce.

In other words: how much waste you generate, what types, and how it’s managed — whether reused, recycled, recovered or sent to landfill.

Here’s what to measure:

- Total waste generated (by weight)

- Waste types (e.g., cardboard, glass, food, electricals)

- Treatment routes (reused, recycled, recovered, disposed)

- Contamination rates (e.g., the wrong materials in recycling bins)

You don’t need to track everything perfectly from day one. Start with what’s available, and build from there. Reliable data helps you:

- Spot where waste is being created

- Improve recycling performance

- Set and track reduction targets

- Report on ESG and sustainability goals with confidence

Accurate reporting shows stakeholders you're taking waste seriously and it gives you the insight to keep improving.

Get your collections and staff engagement right

A zero-waste strategy only works if it’s easy for people to follow. That means setting up your waste collections properly and making sure your teams understand what to do.

Start with the practical stuff. Place bins where waste is actually produced, not just in corridors or back rooms. Use clear, colour-coded signs with images rather than relying on text. Try to keep bins consistent across different sites, so people don’t have to relearn the system. And make it obvious what goes where to reduce contamination.

WRAP has clear guidance on waste segregation that’s worth following and in many cases, you’ll need to meet legal requirements too.

Beyond bins and signage it’s people that make all the difference. Things like having someone on each floor to keep an eye on things, giving new starters a quick intro to the system, setting shared goals, and keeping everyone updated can all help build good habits.

If your setup makes recycling easier than doing the wrong thing, most people will get on board.

Sector snapshots

Every sector has its own waste challenges, but there are quick wins in every industry. Here are a few ideas to help you get started.

Offices

In office environments, paper waste, packaging and tech are common culprits. Go digital where possible to cut down on printing, and standardise desk-side bins across your sites. Set up central drop points for recycling batteries, old IT equipment and packaging, and encourage reuse of supplies with shared stationery cupboards or internal swap schemes.

Retail

Retail businesses deal with a lot of packaging waste and product returns. Work with suppliers to cut unnecessary packaging at the source. Reuse hangers, delivery crates and display materials where possible. Set up clear back-of-store areas for sorting and segregating waste to make recycling easier for staff.

Hospitality

Restaurants, bars, cafés and hotels face high volumes of food and single-use waste. Switch to reusable serviceware where you can, and separate food waste for composting or collection. Partner with food redistribution schemes to deal with surplus stock, and train staff to spot avoidable waste in prep, storage and service.

Manufacturing

Look at where off-cuts or overruns are created and whether they can be reduced or reused. Use precision cutting to reduce waste at source. Work with suppliers to collect and return scrap materials, or set up closed-loop systems for key inputs.

A simple 90-day enterprise zero-waste roadmap

Big changes can feel daunting, but you don’t have to overhaul everything at once. A 90-day plan can help you build momentum and show progress quickly.

Month 1: Get the basics right

Run a baseline audit to see what waste you’re generating and where. Engage suppliers early — ask about packaging reduction, take-back schemes and recycling options. Identify a handful of quick wins, like improving bin signage or rolling out a food waste collection.

Month 2: Pilot a circular initiative

Choose one area to test. That could be a reuse scheme for office supplies, a take-back partnership in retail, or a composting system for food waste in hospitality. Keep it simple, measurable and easy for staff to get behind.

Month 3: Review and share results

Measure progress against your starting point. Share results across teams to build buy-in, and set next-stage goals for scaling up. Even if it’s just a small pilot, showing early results helps prove that a zero-waste approach is both achievable and worthwhile.

How First Mile can help

Moving towards zero waste is easier with the right partner. At First Mile, we help large organisations cut waste and boost recycling with reliable, compliance-led services that are always zero to landfill.

From general waste and office recycling to specialist streams like WEEE, food, cardboard, glass and more, we’ll make sure everything is collected and processed responsibly.

We also provide clear reporting to support ESG goals and Scope 3 waste disclosures, so you can show progress with confidence.

If you’re looking for a simple, scalable way to reduce waste across your enterprise, we’re here to help. Get in touch today to find out how we can help your business cut costs, stay compliant, and hit your sustainability goals.